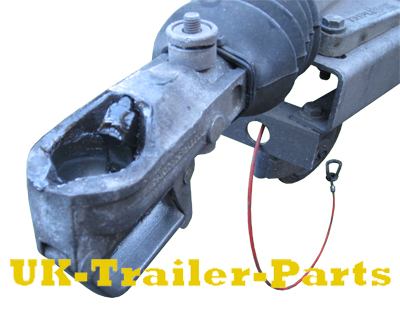

Triple lock head fitting/replacment guide (Braked coupling)

Here is a guide to fitting / replacing a triple lock head on a braked coupling.

First of all you will have to remove your old coupling head.

If you have a standard coupling head you should be able to remove it by undoing the two bolts that fasten it to the drawbar. If you are replacing a triple lock head, things are going to get a little trickier.

Triple lock heads have a small security device that seals one of the bolts securing it to the drawbar. You can only remove this is by cutting through it with a grinder, exposing the bolt on the inside.

The example below shows where to cut through.

You must also turn the head over and cut through the device securing the nut.

Cut the tie wraps from around the rubber bellows and slide them out of the way. Now the bolts have been exposed you can remove them with a ratchet or power tool. Remember though, you will need to use thin walled sockets to fit into the ground off security devices. Spanners and impact sockets will not fit.

Remove the old head from the drawbar.

Slide the new head onto the drawbar and line up the holes where the bolts go. Begin to fit the bolts that secure the head to the drawbar, remembering to fit the new devices that will later seal the bolts.

You will notice that the hole on the side of the head is obscured by something inside the drawbar. This is a damper that connects to the back of the head. It must be levered into position so that a bolt can pass through the eye on the end of it.

Lever the damper with a screwdriver until you can see that the eye of the damper and the holes in the head line up. When they line up, push the bolt through them. This is a little tricky as you will have to hold the damper in place with one hand, while inserting the bolt with the other.

When both bolts are in place tighten them up. Remember that you will need thin walled sockets to fit inside the security device.

Now you can seal the security devices by hammering these small metal disks into them.

The metal disks have tapered edges to make them easier to hammer in.

The metal seal for the device protecting the nut has a hole in the centre of it, this allows it to fit over the end of the bolt. To hammer this into place you will need to use a large socket so that you can hammer the metal disk without hitting the bolt. See the example below.

Turn the head back so it is facing the correct way up and re-fit the rubber bellows. Stretch the bellows back over the coupling head so that it covers the unprotected bolt. Use tie wraps at each end to keep it in place and make a good seal that will keep water out.

If you are looking to buy trailer parts, choose from a large selection at…